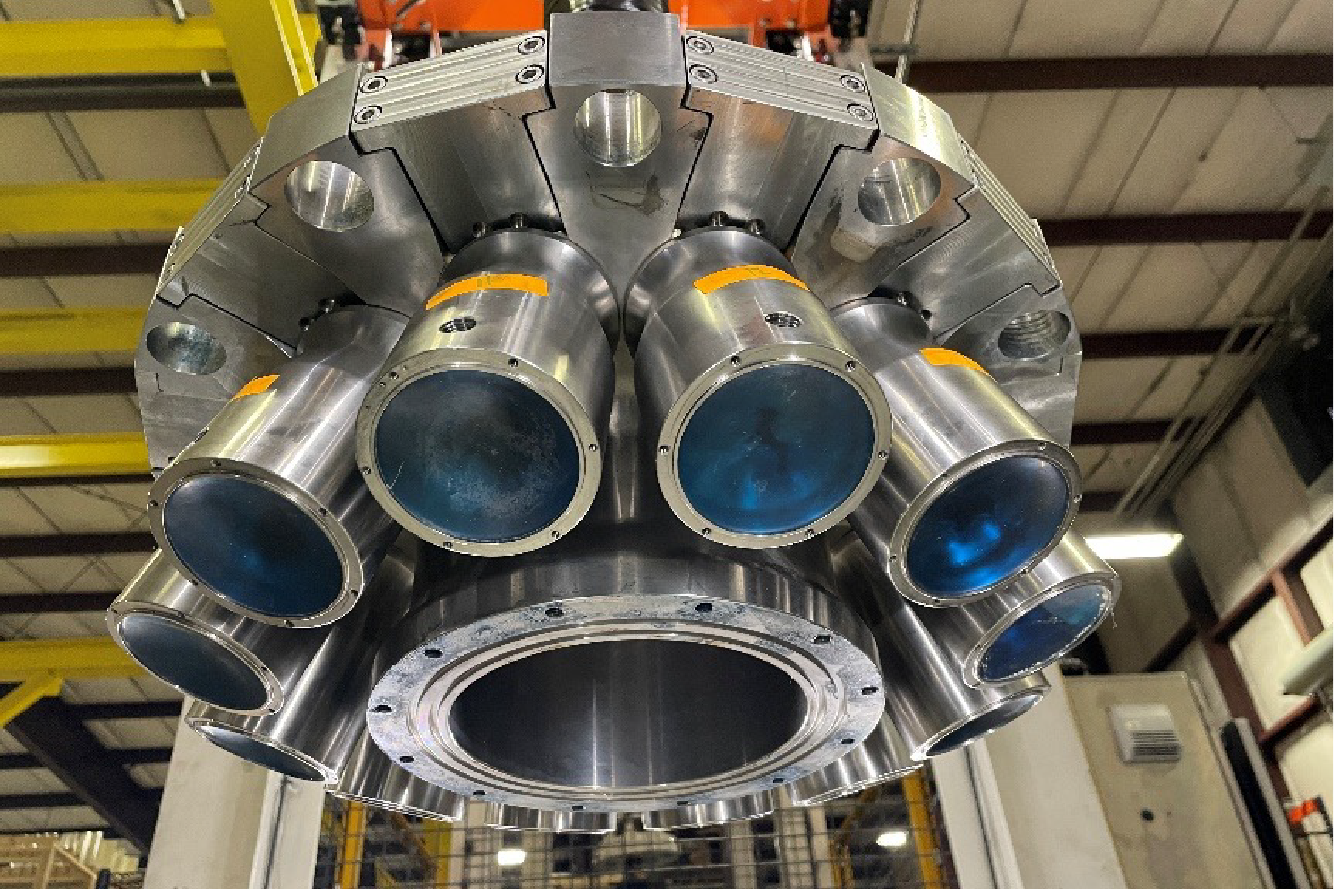

Advanced Termination Technology

Our technology delivers solutions that address many limitations in terminating synthetic tension members, allowing their use in new applications and increasing opportunities in existing applications.

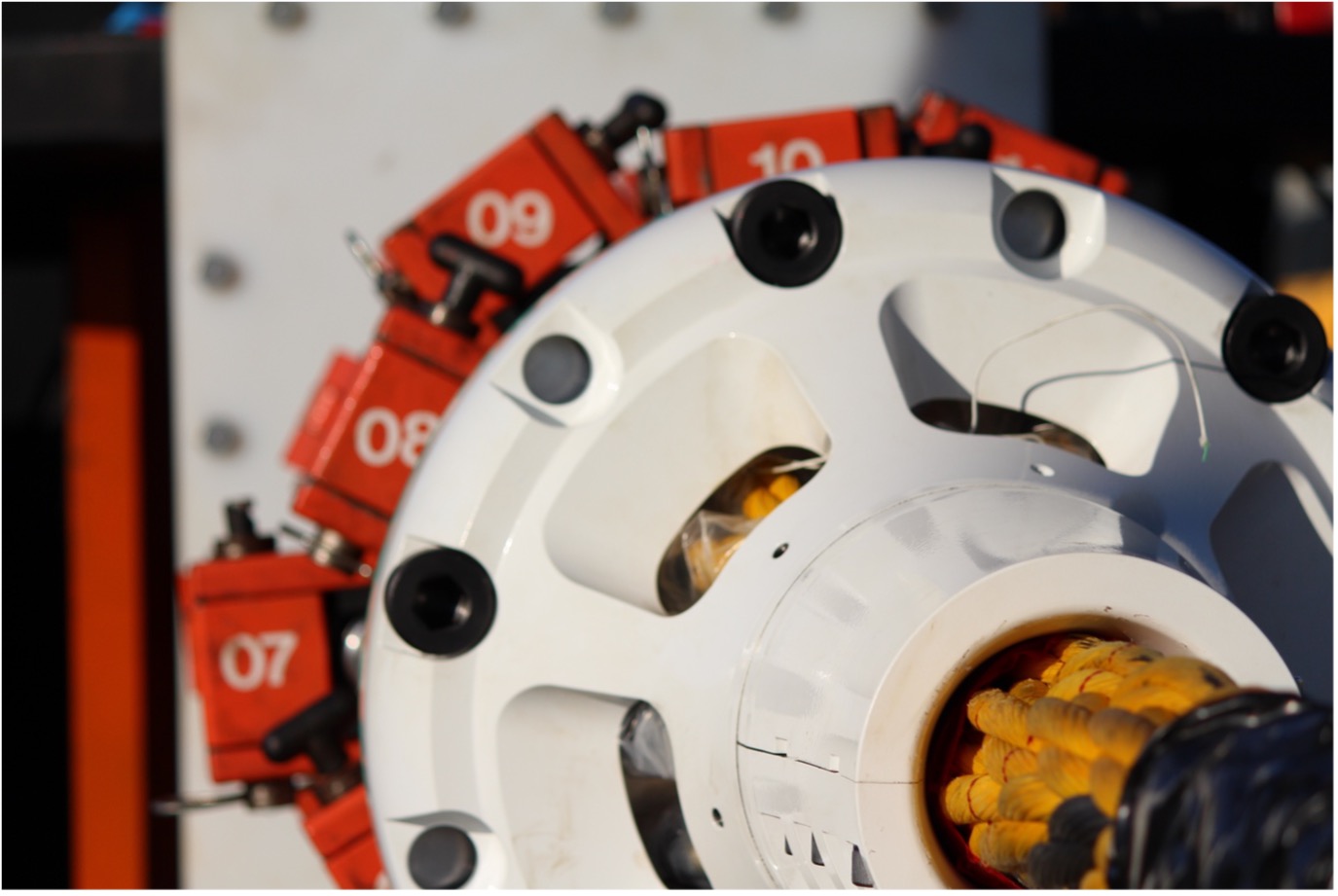

Semi-Automated Process

Fiber rope is generally terminated with a splice which is a manual process requiring highly trained individuals and highly variable. Applied Fiber’s process is DNV certified and semi-automates rope terminations which reduces the variability inherent in manual splicing processes with no negative impact to performance. Scaling up production is equipment dependent and can happen anywhere in the world and deliver product performance and reliability from day one.

Design Flexibility

Unlike a splice which takes only one form, an Applied Fiber termination can be designed in countless ways. The connecting hardware becomes the termination itself resulting in a compact, efficient, and weight saving solution. Features can be integrated seamlessly into the termination delivering intelligence or additional functionality. Applied Fiber technology also enables the manufacture of synthetic rope systems with unsurpassed length tolerances and high-volume repeatability addressing some of the major challenges synthetic tension members have displacing steel.

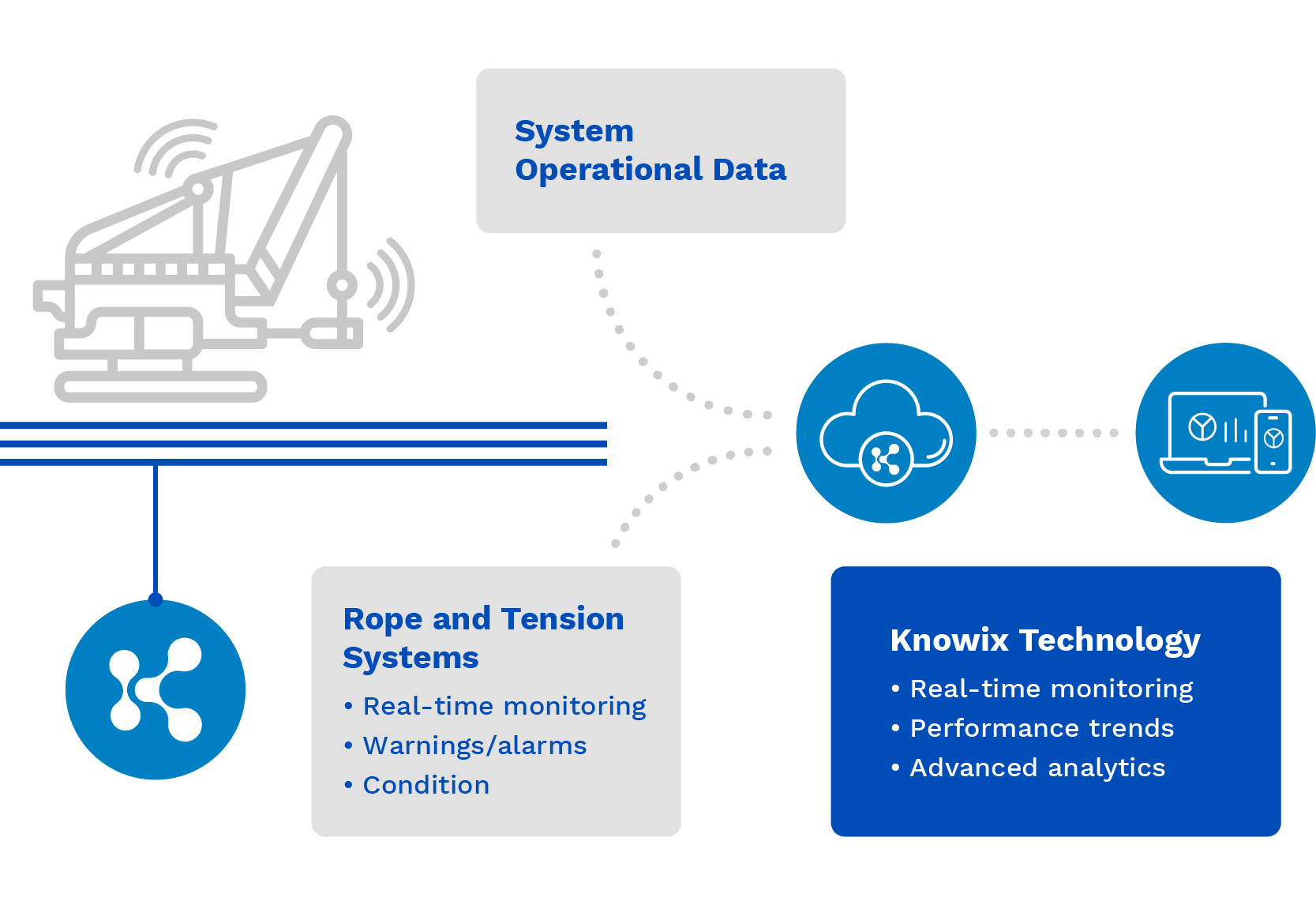

Intelligence

Tension systems despite their common and often critical use, lack intelligence. As the systems where ropes are used have widely implemented digitization, up to now there has not been a way to extend this intelligence to the ropes. Applied Fiber’s terminations deliver a wide range of intelligence solutions to tension members which are built into the termination. This intelligence can range from passive systems like visual wear and overload indicators to fully digital solutions that allow for remote monitoring. Applied Fiber has an exclusive partnership with Knowix to bring their technology to synthetic rope terminations.