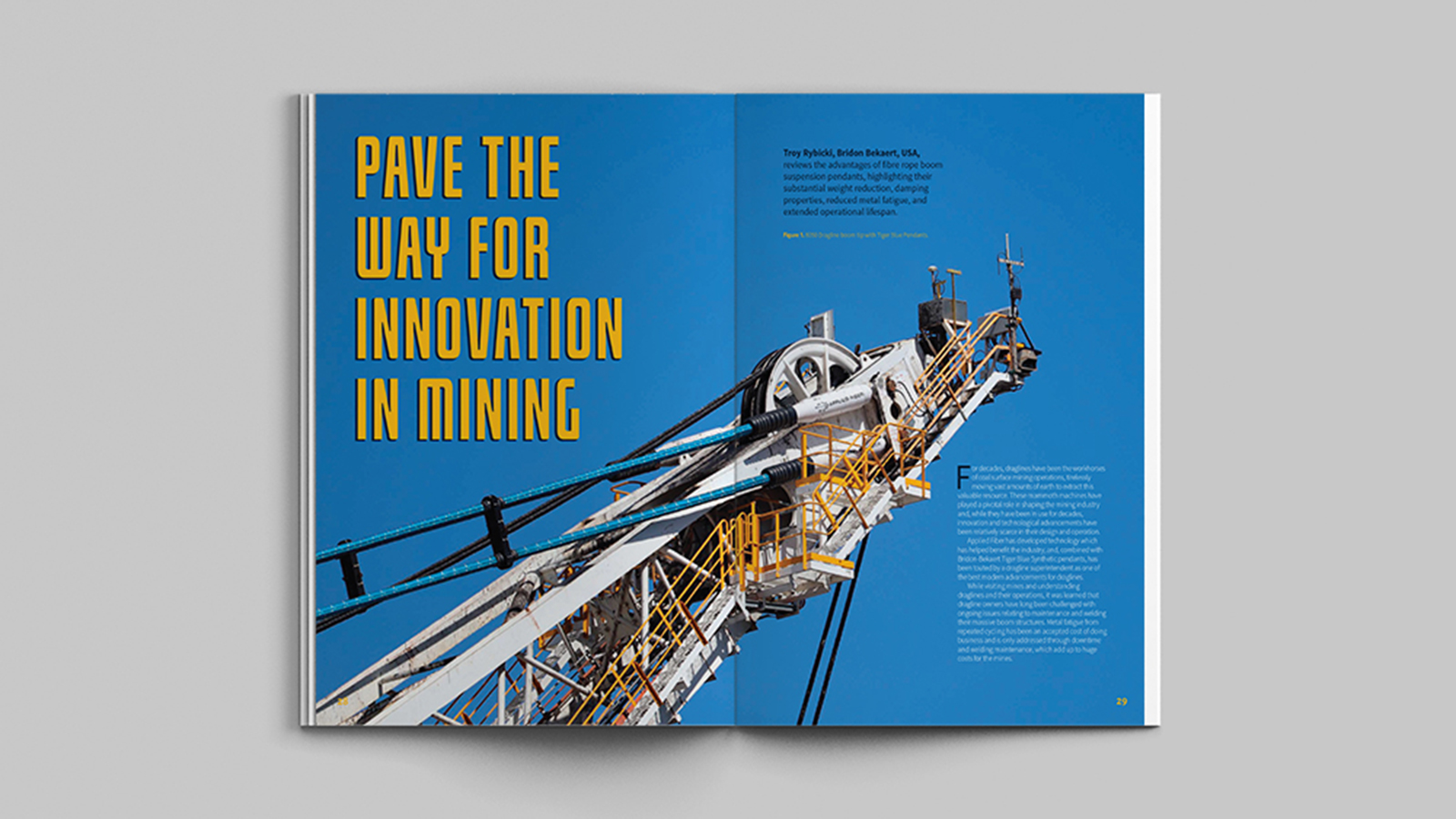

7 Years of Operating Service – Surpass Life of Steel Wire.

Now entering their 7th year of service on a Marion 8200, as expected, Applied Fiber’s Synthetic Fiber Pendants have surpassed the life of steel. The pendants are proving beneficial to both production and maintenance on the largest earth moving machines in the world.

Just recently, the first Dragline Main Fiber pendants installed in 2016 in Wyoming USA had their annual inspection and Applied Fiber was there to witness this milestone event. The pendants are performing even better than anticipated. Where some steel pendants are changed out as soon as every 5 or 6 years, the pendants on this Marion 8200 at NavTec energy appear “just broken in” and that they will far exceed double the life of the steel with numerous additional benefits.

“It’s amazing, aside from some dust on the fibers and some grease on the fittings, the pendants almost look new.” said the inspector of the pendants.

The first-installed set of cables have seen over 1350 peak load cycles daily which equates to over 5.6 million fatigue cycles in this time and they look amazing. The pendants provide the machine, operator, and production a number of benefits, too.

Maintenance at Cloud Peak Energy now NavTec states:

The Applied Fiber pendants are a true step change in dragline technology. We converted the Marion 8229 in 2016, and 8233 in 2017, and a BE1570 lot 12 in 2018 – all of which have really smoothed out the machine operation. On the first 8200, key 29, we effectively increased bucket capacity 2 cu yards (due to increase in soil density) and have had only limited issues operating for six years, a noteworthy change from prior years with steel pendants. The pendants make a huge difference the machine swings well and has noticeably less bouncing and vibration.

The second 8200 we installed the pendant on was getting beat up and we replaced the steel two years early and increased the payload by 5 cu yds (from 82 to 87 cu yds). Since installing the pendants on this machine four years ago the machine now operates much smoother due to the lack of pendant bouncing and overall system damping.

On the 1570, the machine is running much smoother with significantly less fatigue. We would typically see regular cracks in boom nodules #8, #10, and #14… creating 1-2 weeks downtime a year. Since installing fiber pendants three years ago – we have had only minor cracking in this region. We estimate that we have already gained several weeks of production in the three years of operation with the fiber pendants.

Visitors can see the difference from a distance and our operators appreciate how much it quiets the machine movement down. One of our operators went from having numb hands at the end of a shift to having no issues – the difference both in the cab and outside the machine is very noticeable. Putting a low-mass dampener into the boom makes all the difference.

More production, less wear & tear, less downtime, and much smoother operation – NavTec is pleased with what these pendants have done for our draglines. We forecasted just under a two-year ROI and actual performance has met and in many cases exceeded our predictions.”

Since the first install, several draglines in the US and in Australia have been upgraded to fiber pendants. All of these pendants are expected to surpass the life of steel and gain the additional benefits that Navtec achieved.